I have some old rolling-stock which doesn’t fit a Code 75 track. The wheels bump over the ops of the chairs and cause derailment at points and crossovers.

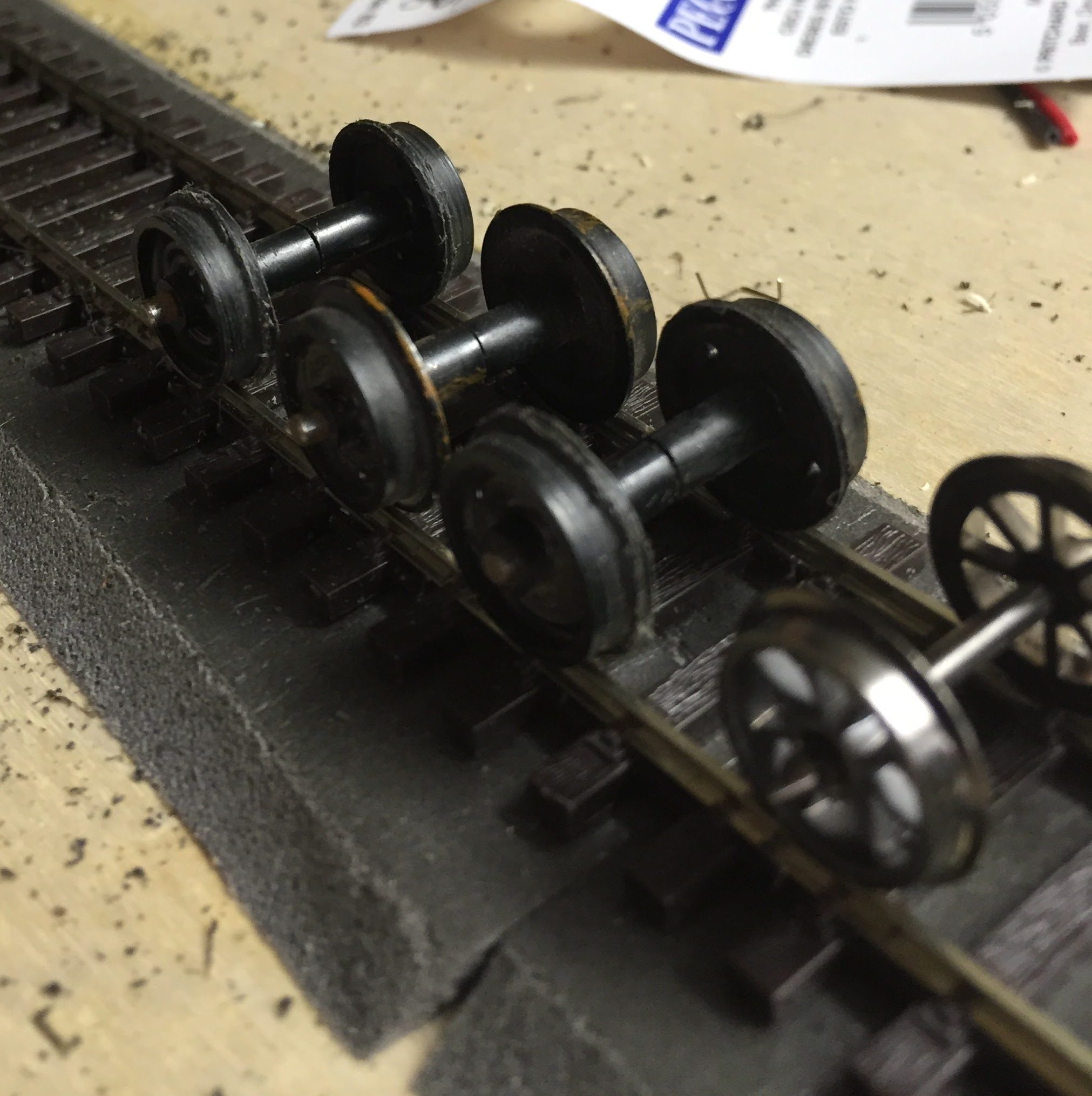

I have some old rolling-stock which doesn’t fit a Code 75 track. The wheels bump over the ops of the chairs and cause derailment at points and crossovers.  A lot of it is 1970s Hornby, which I can update with new pinpoint wheels – no problem. But some is Triang that was still being sold at that date which uses a metal axle and split plastic wheel and axle.

A lot of it is 1970s Hornby, which I can update with new pinpoint wheels – no problem. But some is Triang that was still being sold at that date which uses a metal axle and split plastic wheel and axle.

Here the choice is either to do the fiddly work of inserting brass bearings and supergluing them, or perhaps a cheaper and simpler alternative which does not preclude that option but I thought was worth a shot – turning the wheels down to the correct size. If I ultimately dont like the result, I can just revert to the the other method.

To do this you first have to remove the axle which involves some force to push it through. Once it is off you can then mount the wheel in a lathe, or in my case drill and using a file carefully remove material. I check my progress with a micrometer basing it on a known good new wheel. Once you have the profile you want, you can reassemble and “voila!”. I fixed a rake of 3 gravel hopper trucks (the ones with the lever to dump their contents, 1 tank truck, 1 wooden 12 plank coal truck, a a six-wheel “girder carrying” truck – which is Tresrol wagon.

So now I have tricks that can navigate the points – but will probably sit in sidings mostly. Excuse the “weathering” this was an attempt made in about 1976…. A paint gob is sorely needed.