Automated operation of PDL suffers from a problem once humans enter the picture. How does the computer controlling the storage sidings know what it is being sent and so work out where to put it? Equally for the humans – unless the makeup of mixed goods trains is known on the way out of storage, how can we create movement orders to ensure that the wagons are moved to the right destination.

So, really what we need is a system that can recognize trains and their makeup (length and makeup) as they go into storage.

Enter RFID. Using the cheap type of RFID tags that are implanted in animals, we can “tag” locos, coaches and wagons to produce train makeup information as it passes over an RFID reader.

This is the chip – its about the size of a grain of rice.

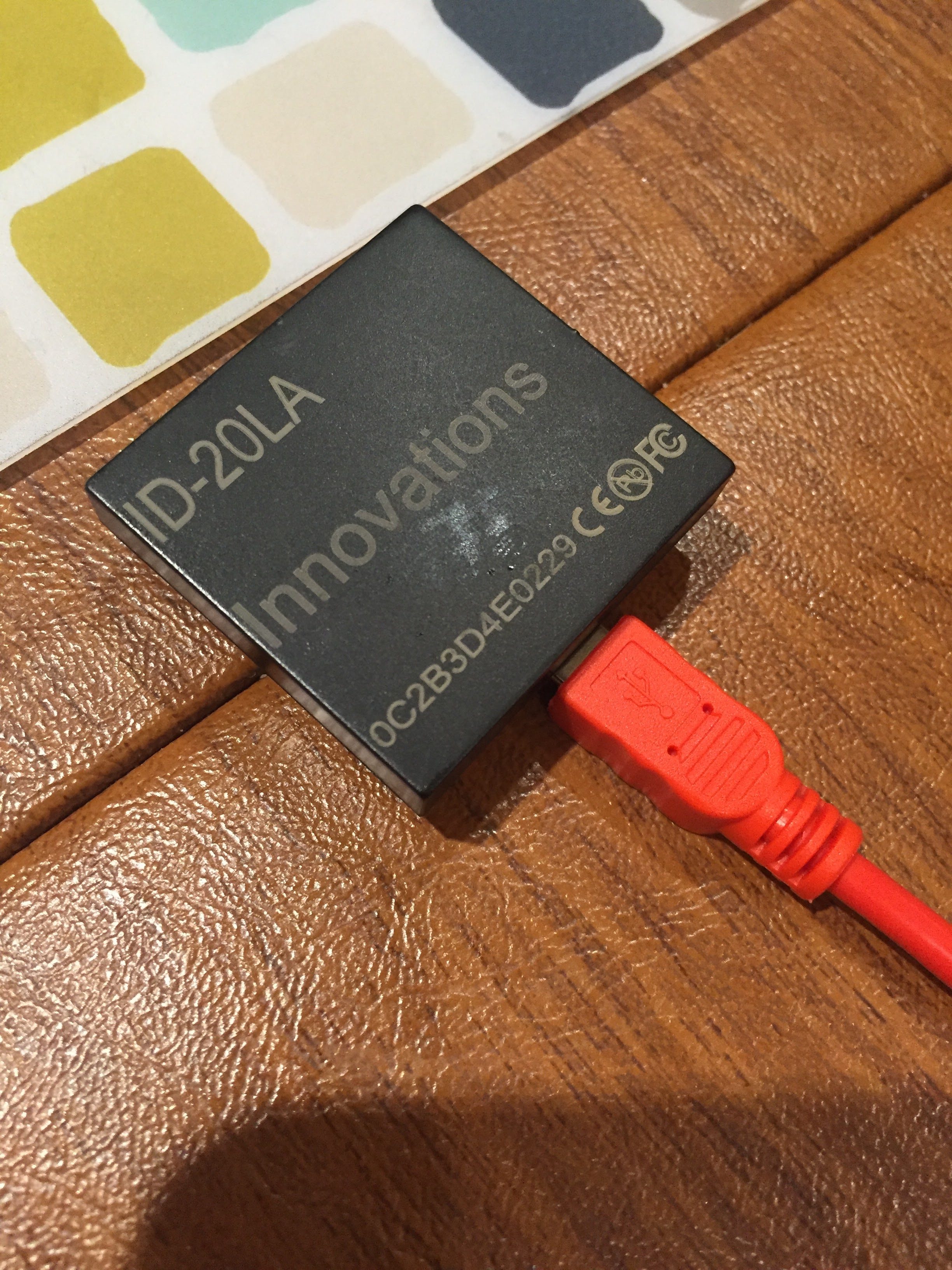

Here is the 1.5″x1.5″ reader mounted onto a USB board.

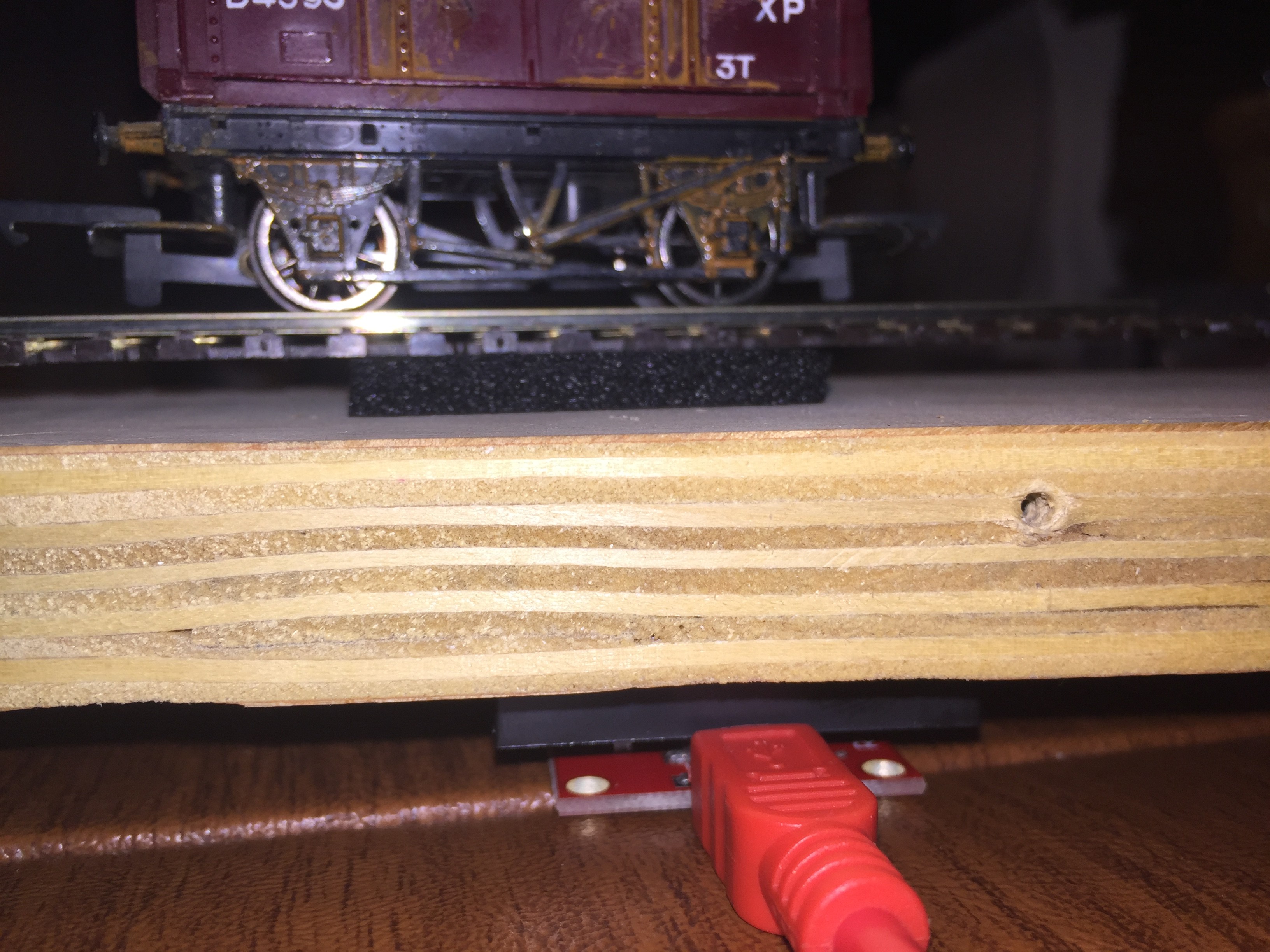

Here is a test of reading ability of the ID-20LA. The chip read while placed in the wagon, which is on the rail, the underlay and the board top. Impressive! This obviates the need to cut a hole in the base under the track.